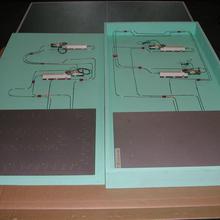

Contour Heat Pipes

- Purpose: Thermal control of spacecraft equipment.

- Year of release: 1992

- Guaranteed service life (years): 25 years after CHP filling with working fluid.

- Estimated production / delivery time (months): 6

- Flight qualification of the product: Yes

- Brief history of flight qualification: Operated successfully on board of more than 30 Russian and foreign satellites.

- Possibility to adapt the product to customer requirements: Yes

| Parameter | Value |

|---|---|

| Transferred heat power | from 2 W to 10000 W |

| Outer diameter of transport lines | from 1 mm to 8 mm |

| Length | up to 10 m |

| Operation temperature range | from -170 C to 80 C |

| Generated capillary pressure | up to 70000 Pa (when Ammonia is used as working fluid) |

Two-phase (vapor/liquid) hermetic closed evaporating/ condensing thermal transfer system filled with a working fluid (usually by Ammonia or Propylene).

CHP advantages:

- CHP design allows to use units for active and passive control of CHP performance;

- CHP can operate at its arbitrary position in the gravity field;

Small pipes diameter allows to bend transport lines that simplifies essentialy CHP integration into the spacecraft;

Condensers of different design (radiators, flow heat exchanges, contact saddles etc.) can be integrated into CHP.

Legal information

Please note that this site is for informational purposes only and under no circumstances is not a public offer determined by the provisions of the Part 2 Article 437 of the Civil code of the Russian Federation.

Information on this site may be changed or supplemented.