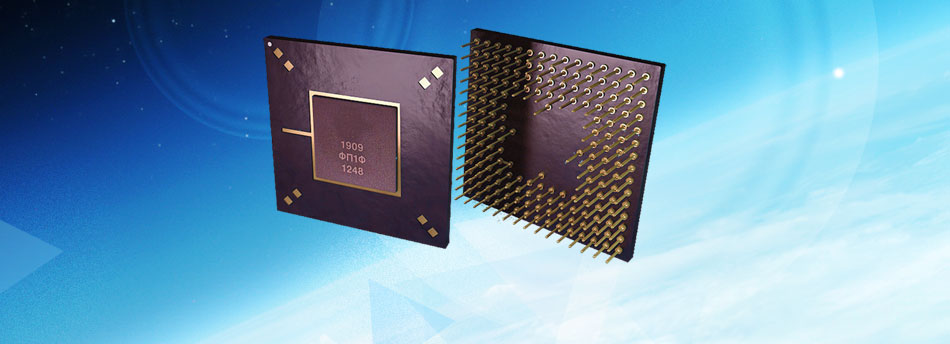

Unified Power Management and Control Module

- Purpose: Power Electronics, Energy.

- Year of release: 2012

- Guaranteed service life (years): 3

- Estimated production / delivery time (months): 8

- Flight qualification of the product: No

- Possibility to adapt the product to customer requirements: No

| Parameter | Value |

|---|---|

| W*H*T | 110х110х10 mm |

| Weight | 30 g |

| Operating temperature range | -40...+105 C° |

| Supply voltage | 4,5...5,5 V |

| Type and performance of the control core | 32 bit RISC, 1.25 DMIPS/mc., |

| Clock frequency | 72 MHz |

| Memory | Static RAM - 64 bytes, ROM (flash) - 512 bytes, DMA controller |

| Set of external interfaces | TTP, CAN, JTAG, USB, SPI, I2C |

| Peripheral modules | ADC 12 bits, 8 channels, DAP 12 bits, 4 channels, thermal meter, PLL, PWM, POR, LDO |

| Operating mods | Active mode, SLEEP, STOP, STANDBY (3 modes) |

| Programmable Gain Values, V/V | 2,8...420 V/V |

| Sweep Input Analog Signals | 2...280 mV/V |

| ADC (pressure meter) digit capacity | 16 bit |

| DAP (pressure meter) digit capacity | 12 bit |

| ADC (temperature meter) digit capacity | 12 bit |

| DAP output signal rise speed | 0,1 V/µs |

| Analog Output Noise, RMS | 0,003 V |

| Analog Output Noise, Peak-Peak | 0,01 V |

| Input Offset Compensation Range | -300...+300 %Vbx |

The unified power control and management module is included in the set of unified modules for critical power management systems. A set of unified modules for critical power management systems designed for use in guaranteed power systems for aircraft engines, electric drives pumping oil, gas, chemical products and other systems of critical use.

The unified power control and management module provides the following main functions in a given temperature range:

- monitoring the load current of each power source and generating a message about the current value according to the CAN and TTP protocols;

- definition of emergency conditions for each power source - “open”, “overload”, “short circuit”, generating a signal to disconnect the power source from the load, generating an emergency status message using CAN and TTP protocols;

- monitoring the status of the secondary power supply (SPS) and generating a status message on the SPS via CAN and TTP protocols;

In addition to monitoring system power, the unified module measures the physical value of the sensor (pressure, coordinate, temperature, vibration velocity, etc.) and generates a message about the value of the physical quantity using CAN and TTP protocols.

Please note that this site is for informational purposes only and under no circumstances is not a public offer determined by the provisions of the Part 2 Article 437 of the Civil code of the Russian Federation.

Information on this site may be changed or supplemented.