Automated Testing Complex ATC

- Purpose: To ensure comprehensive ground-based electrical tests of the spacecraft and verify the operability of its individual systems at the manufacturer of the product and in the operating organization, including for start-up inspections.

- Year of release: 2007

- Guaranteed service life (years): 10

- Estimated production / delivery time (months): 12

- Possibility to adapt the product to customer requirements: Да

| Parameter | Value |

|---|---|

| Galvanic isolation of the test product from the complex | Opto-relay or mechanical relay |

| Universal Communication Interfaces | Ethernet, RS 232/422/485 |

| The issuance of discrete contact and contactless signals. Number of signals | 672 |

| Issuing matrix commands | 32 х 32 |

| Reception of discrete impulse and on-off signals | 1440 |

| DC voltage measurement. Number of channels | 48 channels |

| Entering and processing telemetric information | Yes |

| DC voltage measurement. Number of channels | up to 5 power sources |

| Measurement of resistance and control of insulation resistance of the cable network of the tested product. Number of channels | up to 510 channels |

| Remote control and product monitoring at a distance | up to 250 m |

| Uninterruptible power supplies for the correct completion of the test program in the event of a power failure | IBP |

| Real-time multi-tasking software | QNX, Windows, Microsoft Office, special software for preparing and executing test programs, test software |

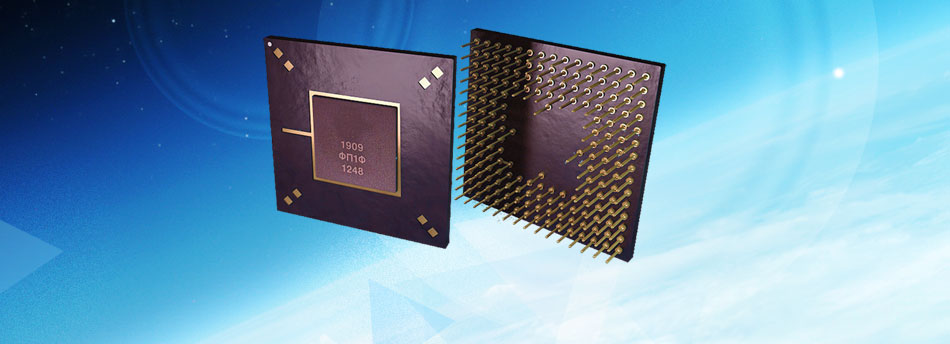

| The switching unit (cross), designed to interface the terrestrial cable network with the complex | 450 x 450 pins per block |

| Spare parts | all replaceable devices |

- ATC has a redundant network structure and is based on industrial computers KI-P1.7, constructs Knurr, Shroff, domestic devices.

- The main ATC devices are made in the form of a personal computer and communication devices with the object.

- Galvanic isolation of the complex from the test product.

- Spare parts for all replaceable devices.

Legal information

Please note that this site is for informational purposes only and under no circumstances is not a public offer determined by the provisions of the Part 2 Article 437 of the Civil code of the Russian Federation.

Information on this site may be changed or supplemented.